Modern embedded platforms are expected to evolve quickly, support feature upgrades, and adapt to new communication and processing requirements without full hardware redesign. Traditional monolithic boards often struggle under these demands because every expansion requires deep rework across the entire system. This slows development cycles and increases validation risk across hardware and firmware layers.

That is where modular board architecture changes the design philosophy. By structuring hardware into functional, interoperable blocks, teams can extend capability with less disruption and greater predictability, often in collaboration with an experienced embedded solution provider that understands lifecycle scaling from prototype to production.

The Core Principle Behind Modular Embedded Architectures

Modular board architecture separates an embedded platform into smaller, purpose-driven hardware units instead of concentrating all functions onto one tightly coupled board. These modules may include compute, power management, connectivity, sensing, or interface boards that interact through standardized connectors and communication buses. Each module is designed with defined electrical and logical boundaries.

This separation reduces cross-dependency between hardware functions and allows designers to upgrade one subsystem without disturbing others. It also improves reuse across product lines, since a validated module can be integrated into multiple variants. From a lifecycle perspective, modularization supports phased upgrades rather than forced redesign cycles. Engineering teams gain flexibility while still maintaining system stability. The result is a more resilient platform structure that supports growth.

Expansion Without Full Redesign Cycles

One of the most practical advantages of modular boards is the ability to expand system capability without restarting the design process from scratch. Instead of respinning an entire PCB for every new feature, engineers can introduce a new module or replace a specific block. This significantly reduces risk, cost, and time.

Expansion becomes structured rather than disruptive. Validation scope remains localized, which simplifies compliance and regression testing. Manufacturing impact is also reduced because core modules remain unchanged across revisions. This approach is particularly useful in industrial, automotive, and IoT environments where feature evolution is continuous. Modular expansion supports predictable roadmaps rather than reactive redesigns.

Interface Standardization

When modules communicate through standardized electrical and protocol interfaces, integration becomes faster and safer. Designers can swap or upgrade modules while maintaining signal integrity and timing expectations. Standard interfaces also improve documentation clarity across teams.

This predictability reduces integration surprises during expansion phases. Firmware teams benefit as well because interface behavior remains consistent across revisions. Standardization, therefore, acts as the backbone of modular scalability.

Connector Strategy and Signal Planning

Connector choice is not just mechanical; it is architectural. High-speed, power, and mixed signal paths must be planned with headroom for future upgrades. A good connector strategy ensures modules can scale bandwidth and current without redesign.

Proper pin mapping and reserved signals allow growth without rewiring logic. This foresight prevents expansion bottlenecks later. It also reduces the need for adapter boards or workaround wiring.

Power Domain Separation

Separating power domains across modules improves fault isolation and upgrade flexibility. A new high-performance module can introduce its own regulation stage without disturbing sensitive analog or control sections.

Independent power zones simplify thermal and electrical validation. They also improve safety margins. Modular power design supports controlled expansion instead of cascading redesign effects.

Faster Prototyping and Iteration Paths

Modular architectures accelerate prototyping because engineers can assemble working systems from validated building blocks. Instead of waiting for a full custom board, teams can iterate using compute modules, interface cards, and add-on functional boards. This supports early firmware development and system testing.

Iteration cycles become shorter because only the changing module requires redesign. Debugging also becomes more targeted since faults can be isolated to a specific hardware block. In lab environments, modular systems support rapid configuration changes for test coverage. This adaptability is valuable in early-stage development as well as late-stage optimization.

Parallel Development Streams

Different teams can develop modules in parallel rather than sequentially. Hardware, firmware, and validation groups can work on separate blocks using agreed interfaces. This reduces project’s critical path length.

Parallel workstreams also improve accountability and traceability. Each module can maintain its own revision control. Integration becomes a managed step rather than a bottleneck.

Reduced Bring Up Complexity

Board bring-up becomes more manageable when core subsystems are already validated in prior modules. Engineers focus only on the new or modified block. This narrows the debug scope and speeds root cause analysis.

Shorter bring-up cycles translate to faster release readiness. It also lowers the risk of hidden coupling faults. Modular validation history compounds over time.

Test Reuse and Qualification Efficiency

Reusable modules come with reusable test plans and qualification data. Environmental and electrical stress results can carry forward with minor delta checks. This reduces repeated certification effort.

Test reuse also improves confidence in field performance. Expansion projects benefit from proven reliability data. That lowers deployment risk.

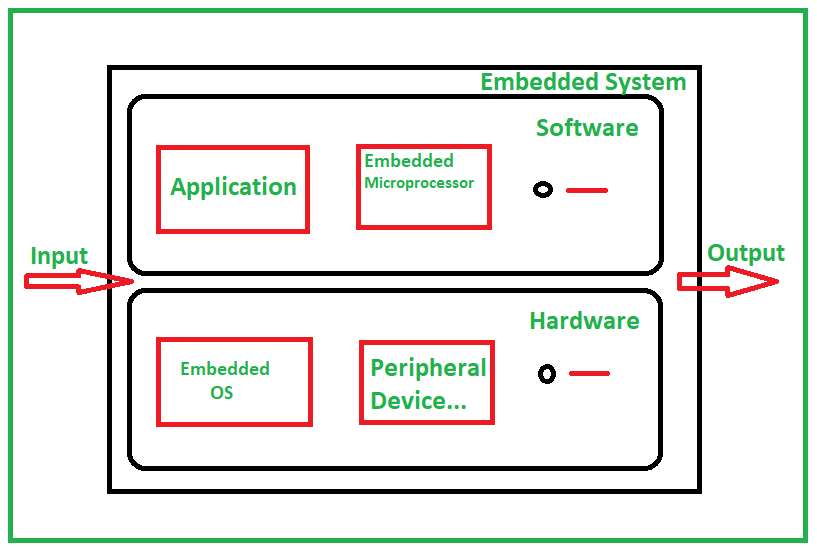

Where Embedded System Design Aligns with Modularity

Modern embedded system design increasingly favors modular hardware patterns because software stacks, connectivity standards, and compute requirements change faster than product lifecycles. A modular board structure allows hardware to keep pace with software-driven evolution. Designers can pair stable baseboards with evolving processor or connectivity modules.

This alignment supports layered architecture thinking across hardware and firmware. Drivers and middleware can map cleanly to hardware modules. Maintenance becomes more structured because the change impact is localized. System documentation also improves when the architecture is block-oriented. Overall, modular thinking connects hardware structure with software scalability in a practical way.

Final Thoughts on Scalable Board Strategies

Modular board architecture is not just a layout preference but a scalability strategy. It supports faster expansion, cleaner validation, and structured lifecycle management across embedded platforms. When executed well, it connects interface planning, power structuring, and PCB layout designing disciplines into a growth-friendly hardware framework.

Engineering organizations that specialize in semiconductor and embedded platforms, such as Tessolve, often work across silicon validation, hardware engineering, and system-level development domains that naturally align with modular hardware thinking. Their case-driven engineering approach reflects how modular strategies help manage complexity across evolving embedded products while keeping expansion practical and controlled.